Sand casting creates metal parts by pouring molten metal into molds made from sand. The process is reliable and cost-effective, but it’s also prone to various defects that can ruin a casting.

These defects happen when something goes wrong with the sand, the pouring process, or the mold design. As a foundry operator or technician, you’ll encounter blowholes, shrinkage cavities, surface cracks, and other problems that affect both appearance and structural integrity.

Gas defects form when air or gases get trapped in the molten metal during pouring and solidification. These are among the most common problems you’ll see in sand castings, showing up as holes, voids, or porous areas on or beneath the surface.

Blowholes are rounded or oval cavities that form when gases can’t escape from the mold cavity. You’ll typically find them on the cope (upper) part of the casting, where gases naturally rise.

Pinholes are tiny gas-related defects measuring about 2mm in diameter. They usually appear in clusters rather than individually, creating a rough, porous surface texture.

Gas porosity refers to small voids distributed throughout the casting’s interior. Unlike blowholes and pinholes that you can see, porosity often remains hidden until you machine or section the part.

Gases get trapped during solidification because they dissolve in liquid metal but can’t stay dissolved in solid metal. As the casting cools and solidifies, these gases must go somewhere.

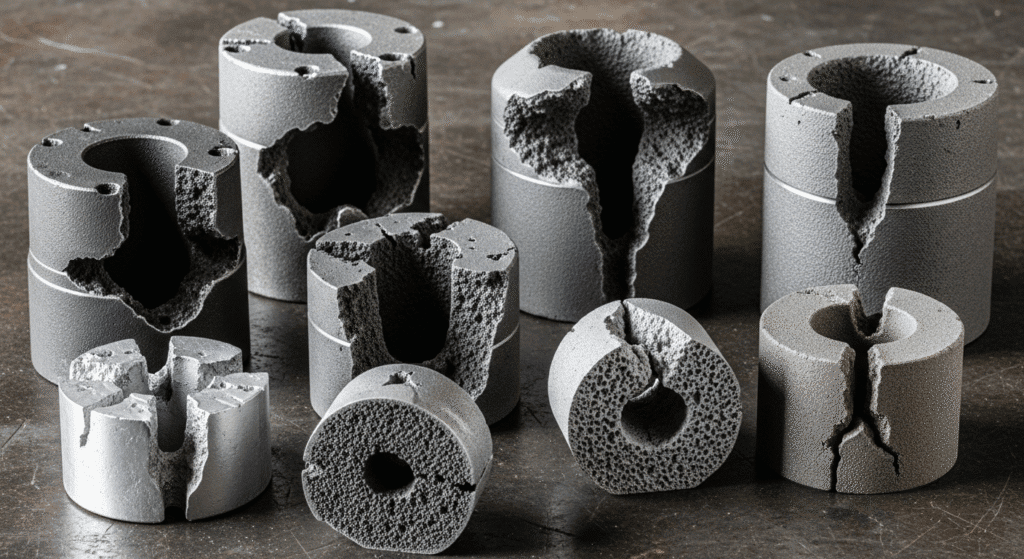

Shrinkage defects occur when molten metal contracts as it solidifies but doesn’t receive enough additional liquid metal to fill the resulting void. These defects severely compromise casting strength and are among the most serious quality problems you’ll encounter.

Hot spots are areas in your casting that solidify last because they retain heat longer than surrounding sections. These typically occur where the casting has thicker sections or where multiple sections meet.

Shrinkage cavities are voids that form at hot spots when the solidifying metal doesn’t get fed with additional liquid metal. These defects severely weaken your casting and often require scrapping the part.

You’ll encounter two types of shrinkage defects:

Open shrinkage appears as a depression or crater on the casting surface, usually at the top where the riser feeds the part. You can see this type immediately after removing the casting from the mold.

Closed shrinkage forms as internal voids that don’t break through to the surface. These are more dangerous because they hide inside the casting and only reveal themselves during machining or, worse, when the part fails in service.

Surface defects appear as irregularities on the outer face of your casting. These problems affect both appearance and dimensional accuracy, often requiring extensive grinding or causing you to scrap the part entirely.

Rat tails appear as irregular lines or cracks on the casting surface, looking like thin, wavy grooves. When these defects become severe, they’re called buckles, which are essentially large, pronounced rat tails.

The appearance is distinctive. You’ll see one or more irregular grooves running along the outer surface, typically on flat sections of the casting. These lines follow a somewhat random pattern but generally run in the direction of sand expansion.

Metal penetration occurs when liquid metal seeps into gaps in the molding sand, creating a rough, uneven surface finish on your casting. You can identify this defect by the visible roughness and grainy texture on the casting surface.

The appearance is unmistakable. Instead of a smooth surface, you’ll see what looks like sand grains fused to the metal. The penetration creates an irregular, bumpy texture that’s rough to the touch.

Scabs are irregular metallic crusts that appear on the casting surface, typically only a few millimeters thick. They’re closely related to rat tails and often appear together on the same casting.

The relationship to rat tails is direct. When you remove a scab from the casting surface, you’ll typically find a rat tail underneath. Both defects result from sand expansion and compression failure, but scabs represent a more severe case where a piece of the mold face actually lifts up, and metal flows underneath it.

Incomplete filling defects occur when molten metal doesn’t completely fill the mold cavity or when two streams of metal fail to merge properly. These defects leave you with parts that are either missing sections entirely or have weak spots where the metal didn’t fuse.

A misrun happens when liquid metal doesn’t completely fill the mold cavity, leaving an unfilled portion of your casting. You’ll immediately recognize this defect because part of your casting is simply missing.

The incomplete filling shows several characteristics:

Cold shuts form when two fronts of liquid metal meet in the mold cavity but don’t fuse properly, leaving a discontinuity or weak spot in your casting. This defect creates a serious structural weakness.

The merging failure happens because the metal streams have already started to solidify. When liquid metal flows around a core or obstacle, it splits into two or more streams. These streams should merge seamlessly on the other side, but if they’ve cooled too much, they just press against each other without fusing.

Visual identification is relatively straightforward. You’ll see a visible line or crack where the two streams met. The line appears as a thin, irregular seam running across the casting surface. Sometimes it looks like a crack, and in other cases, it appears as a faint line with a slightly different texture.

Inclusion defects occur when non-metallic materials get trapped in your casting. These foreign materials create weak spots, reduce mechanical properties, and can cause failure in service.

Slag inclusions are non-metallic materials that create pockets or ribbon-like entrainments in the casting. They’re highly irregular and porous in shape, and you’ll often find them in the upper parts of castings where they float to the surface.

Non-metallic material entrapment happens during melting and pouring. Slag forms when elements in the melt with high oxygen affinity react with oxygen in the air, creating oxide compounds that float on the melt surface. In steel casting, this reaction is particularly pronounced.

Sand inclusions occur when sand particles from the mold become embedded in the casting material. You’ll find this defect in virtually all sand castings to some degree, but too much sand inclusion ruins the part.

Sand particles get embedded during pouring when loose sand from the mold wall gets carried along by the metal stream or falls into the mold cavity. The particles then get trapped as the metal solidifies around them.

Multiple factors contribute to sand casting defects, often working together to create problems.

| Defect Type | Primary Causes | Contributing Factors |

|---|---|---|

| Blowholes | Excessive moisture (>4%), low sand permeability | Insufficient venting, over-rammed molds, fine sand grains |

| Pinholes | High moisture content, hydrogen absorption | Wet ladles, inadequate degassing, poor sand drying |

| Gas Porosity | Trapped gases during solidification | Low permeability sand, turbulent pouring, chemical reactions |

| Shrinkage Cavities | Inadequate feeding system, hot spots | Wall thickness variations, riser modulus <1.2x casting, poor riser placement |

| Rat Tails | Poor sand expansion properties, excessive heat | Overly hard ramming, large flat sections, insufficient hot strength |

| Metal Penetration | Coarse sand grains, high pouring temperature | No mold wash, low sand strength, excessive permeability |

| Scabs | Sand expansion and compression failure | Same as rat tails, severe mold face lifting |

| Misruns | Low pouring temperature, poor fluidity | Small gates, slow pouring rate, thin casting sections |

| Cold Shuts | Low metal temperature, streams not fusing | Poor gating design, slow pouring, inadequate fluidity |

| Slag Inclusions | Incomplete slag removal, pouring technique | Contact with air, turbulent pouring, no slag trap |

| Sand Inclusions | Mold erosion, loose sand particles | Uneven compaction, turbulent flow, weak cores, poor mixing |