The main difference between 304 and 316 stainless steel is that 316 contains 2-3% molybdenum while 304 has none, giving 316 superior corrosion resistance especially against chlorides and making it about 20-50% more expensive than 304.

Both are austenitic stainless steels with excellent overall properties. 304 works perfectly for most indoor and general applications, while 316 excels in marine environments and chemical processing where its extra corrosion resistance justifies the higher cost.

| Element | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium (Cr) | 18.0-20.0% | 16.0-18.0% |

| Nickel (Ni) | 8.0-10.5% | 10.0-14.0% |

| Molybdenum (Mo) | 0% (none) | 2.0-3.0% |

| Carbon (C) | ≤0.08% | ≤0.08% |

| Manganese (Mn) | ≤2.0% | ≤2.0% |

| Silicon (Si) | ≤0.75% | ≤0.75% |

| Phosphorus (P) | ≤0.045% | ≤0.045% |

| Sulfur (S) | ≤0.030% | ≤0.030% |

The molybdenum in 316 is the game-changer. This single addition dramatically improves resistance to pitting and crevice corrosion, especially in chloride environments.

Grade 304 is often called “18/8” stainless for its chromium and nickel content. Meanwhile, 316’s molybdenum content earns it the nickname “marine grade” stainless steel.

Despite their different chemical compositions, 304 and 316 share remarkably similar physical properties:

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Density | 8.0 g/cm³ | 8.0 g/cm³ |

| Melting Point | 1450°C (2640°F) | 1400°C (2550°F) |

| Thermal Conductivity | 16.2 W/m·K at 20°C | 16.3 W/m·K at 20°C |

| Thermal Expansion | 17.2 ×10⁻⁶/K at 20°C | 15.9 ×10⁻⁶/K at 20°C |

| Modulus of Elasticity | 193 GPa | 193 GPa |

| Electrical Resistivity | 0.72×10⁻⁶ Ω·m at 20°C | 0.74×10⁻⁶ Ω·m at 20°C |

Both grades have identical density and elastic modulus. Their thermal properties are nearly the same, with 304 having a slightly higher melting point by about 50°C.

The electrical conductivity of both steels is relatively low—only about 2-3% that of copper. This makes them poor electrical conductors but excellent for applications requiring electrical insulation properties.

In their annealed condition, 304 and 316 deliver comparable mechanical performance with subtle differences:

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Yield Strength | 205-215 MPa (min. 210 MPa) | 200-240 MPa (min. 205 MPa) |

| Tensile Strength | 515-720 MPa | 485-620 MPa |

| Elongation at Break | 40-50% | 40-50% |

| Hardness | ≤95 HRB (201-215 HB) | ≤95 HRB (146-149 HB) |

| Modulus of Elasticity | 193 GPa | 193 GPa |

Grade 304 typically shows slightly higher tensile strength and hardness than 316. For instance, 304 can reach Brinell hardness values up to 215 HB compared to 316’s maximum of about 149 HB.

Both alloys maintain excellent ductility with 40-50% elongation, making them easy to form and fabricate. Neither can be hardened by heat treatment—they can only be strengthened through cold-working processes.

Corrosion resistance is where 316 truly shines compared to 304. Both grades form a protective chromium oxide layer, but 316’s molybdenum content provides crucial advantages.

General Corrosion: In normal atmospheric conditions and mild environments, both grades perform excellently. Neither will rust under typical indoor conditions or with exposure to fresh water.

Chloride Environments: This is 316’s strongest advantage. Grade 304 can experience pitting corrosion with chloride levels as low as 25 ppm. This makes it unsuitable for marine applications or anywhere exposed to de-icing salts.

Grade 316 resists chloride-induced corrosion far better. Its molybdenum content increases its Pitting Resistance Equivalent Number (PREN), allowing it to withstand saltwater, brine, and coastal environments where 304 would quickly fail.

Chemical Resistance: The molybdenum in 316 improves resistance to reducing acids like sulfuric and phosphoric acid. While 304 handles oxidizing acids like nitric acid well, 316 performs better across a wider range of chemical exposures and concentrations.

Stress Corrosion Cracking: Both grades can suffer from stress-corrosion cracking in hot chloride solutions above 50-60°C. While 316 offers slightly better resistance, neither grade is immune to this failure mode.

Grade 316 costs approximately 20-50% more than 304, with the typical premium hovering around 40%. This price difference stems from two factors:

Both nickel and molybdenum are expensive alloying elements whose prices fluctuate with commodity markets. This makes 316’s price premium variable but consistently significant.

For budget-conscious projects where 304’s corrosion resistance is adequate, the extra cost of 316 isn’t justified. However, when failure from corrosion would result in expensive repairs or safety risks, 316’s higher upfront cost often pays for itself through reduced maintenance and longer service life.

The choice between 304 and 316 often comes down to the specific environment and cost considerations.

304 Stainless Steel Applications:

316 Stainless Steel Applications:

It depends on your location. Grade 304 works well for inland areas without salt exposure, while 316 is essential for coastal regions or anywhere exposed to de-icing salts.

Yes, you can weld them together using appropriate filler materials, though the weld zone will have mixed properties between the two grades.

No, both 304 and 316 are non-magnetic in their annealed state but can become slightly magnetic when cold-worked.

The “L” stands for low carbon (≤0.03%), which improves weldability by preventing carbide precipitation at grain boundaries.

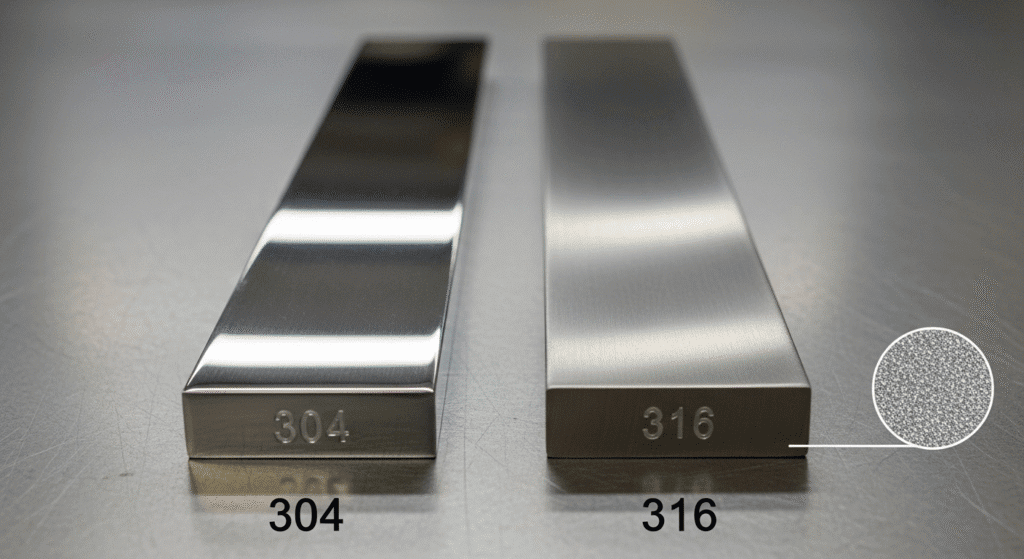

Without chemical testing, they look identical. A molybdenum spot test kit can distinguish them—316 will show a positive reaction while 304 won’t.

In chloride or chemical environments, 316 lasts significantly longer. In normal indoor conditions, both grades can last decades with no noticeable difference.