Steel is often specified for “strength”–yet ductile iron delivers higher yield strength (40 ksi vs 36 ksi). That misconception costs foundries and their customers money every day.

Consider this: A hydraulic bushing converted from 1144 steel to 65-45-12 ductile iron barstock resulted in a 30 percent cost reduction. The machine shop doubled turning speeds from 650 sfm to 1,400 sfm while reducing cycle time by 2 minutes per part–with no difference in tool life.

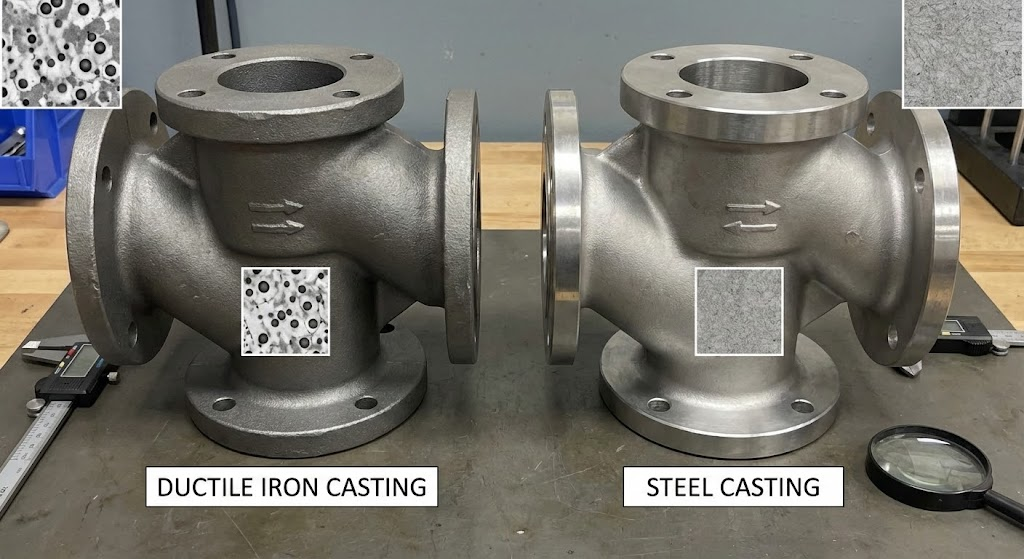

Material selection between ductile iron and steel depends primarily on three factors: assembly method (welded vs bolted), operating temperature, and cost sensitivity. Strength rarely determines the choice.

This guide provides the quantified comparison data and decision framework you need to select the optimal material for your specific application.

Ductile iron matches or exceeds steel in most strength metrics that matter for casting applications. For bolt-together assemblies operating within standard temperature ranges, I recommend ductile iron as the default choice–steel specification requires justification, not the other way around.

| Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) |

|---|---|---|---|

| Ductile Iron 60-40-18 | 60,000 | 40,000 | 18 |

| Ductile Iron 65-45-12 | 65,000 | 45,000 | 12 |

| Ductile Iron 80-55-06 | 80,000 | 55,000 | 6 |

| Ductile Iron 100-70-03 | 100,000 | 70,000 | 3 |

| Cast Steel (WCB/WCC) | 70,000 | 36,000 | 22 |

While tensile strengths are comparable, ductile iron has the greater yield strength at 40 ksi. Cast steel can only reach 36 ksi yield strength. Engineers who specify steel for “higher strength” often overlook this yield advantage.

ADI processing transforms standard ductile iron into a steel-competitive material with tensile strengths reaching 200 ksi.

| ASTM A897 Grade | Tensile (ksi) | Yield (ksi) | Elongation (%) |

|---|---|---|---|

| 110/70/11 | 110 | 70 | 11 |

| 150/110/07 | 150 | 110 | 7 |

| 200/155/02 | 200 | 155 | 2 |

The austempering process creates an ausferrite structure that delivers twice the strength for a given ductility compared to pearlitic, ferritic, or martensitic microstructures.

Specify ADI when you need steel-level tensile strength with superior damping and noise reduction. Heat-treated ductile iron gears achieve approximately 90 percent of the fatigue strength of 8620 carburized and hardened gears. ADI gears reach 93 percent–with noise reductions of 8-20 dB.

Steel holds a clear advantage in impact and ductility performance. This is not a marginal difference.

Steel pipe typically exhibits Charpy impact values 3 to 30 times higher than ductile iron pipe at normal operating temperatures. Elongation values run 2 to 4 times higher for steel.

When to specify steel for impact performance:

However, ferritic ductile iron (60-40-18) maintains excellent fracture toughness to temperatures as low as -62C (-80F). For standard industrial temperature ranges, this grade handles most low-temperature applications without the cost premium of steel.

Ductile iron offers significant advantages in both casting efficiency and machining economics. These process differences translate directly to cost savings.

| Material | Shrinkage | Pattern Allowance | Riser Impact |

|---|---|---|---|

| Ductile Iron | 0.5-1.0% | 5-10 mm/m | Smaller risers required |

| Cast Steel | 1.5-2.0% | 20 mm/m | Larger risers, more waste |

Why the difference? Graphite precipitation during solidification counteracts metal contraction in ductile iron. The higher carbon content promotes graphite formation, and silicon enhances this effect while reducing carbide tendency.

For pattern makers: ductile iron’s lower shrinkage allows tighter as-cast tolerances. This reduces machining stock requirements and minimizes material waste in risers.

Ductile iron machines at roughly twice the speed of steel with equivalent or better tool life.

A documented case study shows the user was able to increase turning speed from 650 sfm to 1,400 sfm when converting from steel to ductile iron. Cycle time was reduced by 2 minutes without any difference in tool life.

The mechanism: Silicon content reduces ferrite toughness, making cutting easier. Graphite spheres provide natural lubrication at the cutting interface. This combination enables the dramatic speed increase.

Cost impact: A hydraulic bushing converted from 1144 steel to 65-45-12 ductile iron barstock resulted in a 30 percent cost reduction. If your application involves significant machining, ductile iron should be your default material choice.

Lower shrinkage translates to tighter as-cast dimensions, reducing or eliminating machining operations.

One case study demonstrates the potential: Computer modeling with sound technical communications resulted in an iron casting design that reduced mass by 41 percent and machined stock by 60 percent compared to the original steel design.

This weight reduction also improves strength-to-weight ratio–a single casting can produce multiple components while running 10 percent lighter than steel equivalents.

Temperature and corrosion performance determine material selection for many applications. Steel extends slightly higher in temperature capability, but ductile iron delivers significantly better corrosion resistance.

| Material | Min Temp | Max Temp | Notes |

|---|---|---|---|

| Ductile Iron | -30C (-22F) | 350C (662F) | Thermal limit ~730C |

| Carbon Steel | -29C (-20F) | 425C (797F) | Extended high-temp capability |

| Ferritic DI (60-40-18) | -62C (-80F) | 350C (662F) | Excellent low-temp toughness |

Steel wins for high-temperature applications above 350C. For continuous service exceeding this threshold, specify carbon steel.

However, ferritic iron vs ductile iron grades maintain excellent toughness to -62C–adequate for most industrial low-temperature applications.

Ductile iron significantly outperforms steel in corrosion resistance.

A 14-day cyclic corrosion test showed ductile iron exhibited a significantly lower corrosion rate of 1.3 mm/year compared to Q235 steel at 2.8 mm/year.

Why the difference? Graphitic corrosion residue adheres to the substrate, slowing further attack. Steel lacks this self-protective mechanism and typically requires coatings for corrosion protection.

The service life impact is dramatic: Ductile iron valves are renowned for their long lifespan, often lasting 60 to 80 years. Steel valves typically last around 25 to 30 years.

For applications where coating maintenance is difficult or expensive, ductile iron provides inherent corrosion resistance without additional protection.

Welding capability often determines material selection regardless of other performance factors. If your design requires structural welding, steel is typically the only practical choice.

High carbon content–3.0-3.9 percent in ductile iron versus 0.08-0.60 percent in cast steel–creates fundamental welding difficulties.

Technical problems include:

As one welder on the WeldTalk forum) put it: “Repairing ductile iron pipe is ‘a bear’ requiring preheat, 7018 rods on low amps, and post heat. Many would not repair anything ductile that was going to have much of a load on it.”

For structural welded joints, specify steel. The difference between cast steel and forged steel matters less than the fundamental weldability advantage both offer over ductile iron.

Successful ductile iron welding is possible but demands:

CAUTION: Verify your welder’s experience with ductile iron before specifying welded DI for load-bearing applications. Many experienced practitioners avoid it entirely.

For flanged connections and bolted joints, ductile iron becomes the superior choice.

The average damping capacity for ductile iron is 6.6 times greater than SAE 1018 steel. This translates to:

If your assembly method permits bolted connections, ductile iron’s combination of damping, machinability, and corrosion resistance makes it the preferred material.

For most applications, ductile iron delivers superior cost-performance ratio. The 30 percent cost reduction case study mentioned earlier represents typical conversion savings.

Ductile iron casting costs less than steel for several reasons:

Lower pouring temperature reduces energy consumption and extends furnace lining life.

Lower shrinkage (0.5-1.0% vs 1.5-2.0%) means smaller risers and less material waste. Pattern design is simpler when shrinkage in casting defects is less severe.

Simpler process requirements–steel often requires specialized casting processes like investment casting or lost foam. Ductile iron handles green sand casting efficiently.

Machining represents the largest cost advantage for ductile iron.

At 2x the cutting speed with equivalent tool life, cycle times drop significantly. The 2-minute per part reduction documented in the conversion case study compounds across production volumes.

Tool life remains equivalent or better despite doubled speeds. This reduces tooling expense and machine downtime for tool changes.

Ductile iron’s service life advantage compounds over decades:

This 2-3x lifespan difference often justifies initial material selection even when steel appears cheaper at purchase.

Steel typically requires corrosion protection coatings. Maintenance costs for coating renewal add to total lifecycle expense. Ductile iron’s inherent corrosion resistance eliminates this ongoing cost.

Use this framework to systematically evaluate your application requirements against material capabilities.

Choose ductile iron when:

For bolt-together assemblies with standard temperature requirements, ductile iron delivers superior cost-performance ratio–30% cost reduction potential with equivalent or better service life.

Choose steel when:

| Application Factor | Choose DI | Choose Steel |

|---|---|---|

| Assembly method | Bolted/flanged | Welded |

| Operating temp | -30C to 350C | >350C or specialized |

| Impact loading | Moderate | Extreme |

| Vibration/noise | Critical | Not a concern |

| Cost sensitivity | High priority | Lower priority |

| Machining volume | High | Low |

| Required service life | 60+ years | 25-30 years acceptable |

| Corrosion environment | Moderate, uncoated | Coated acceptable |

Both materials respond to heat treatment, but the options and outcomes differ significantly.

Standard heat treatment in metal casting for ductile iron includes:

Annealing maximizes ductility–produces the 60-40-18 ferritic grade with 18% elongation.

Normalizing improves strength and hardness for moderate wear applications.

Austempering (ADI) doubles strength for a given ductility level. The process involves:

The result: Ausferrite structure with superior strength-to-ductility ratio.

Alloying considerations for ADI: Add Ni, Mo, Cu (up to 0.8%) for hardenability. Limit Mn to less than 0.3% to avoid segregation issues.

Steel offers a broader range of heat treatment options:

Normalizing, quench-and-temper, carburizing–well-established procedures with predictable outcomes.

Steel heat treatment procedures are more straightforward than ADI processing. If your application requires surface hardening through carburizing, steel may be the simpler choice.

For gear applications specifically:

Heat-treated ductile iron gears have approximately 90 percent of the fatigue strength of 8620 carburized and hardened gears. Austempered ductile iron gears achieve 93 percent.

Noise reduction in automotive balance shaft gears has been reported as much as 20 decibels for gray iron. Ductile iron gears show noise reductions of 8 decibels compared to steel.

The cost advantage: ADI processing is less expensive than carburizing. For applications where 90-93% of steel fatigue performance is acceptable, ADI gears offer significant cost savings with improved noise characteristics.

Material selection between ductile iron and steel reduces to three primary factors: welding requirements, temperature limits, and cost sensitivity. Mechanical strength rarely determines the choice–ductile iron matches or exceeds steel in most relevant metrics.

Ready to discuss material selection for your specific casting application? Our metallurgists can evaluate your requirements and recommend the optimal material choice. Contact our engineering team to start the conversation.